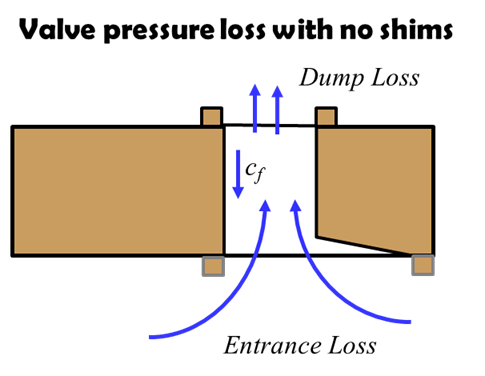

Here is a look at the port flow loss dyno tests with all shims removed and comparing those to ReStackor. The port flow losses for ReStackor are much higher.

For the dyno tests with all shims removed the dyno is measuring the port entrance loss, friction loss and dump loss at the exit.

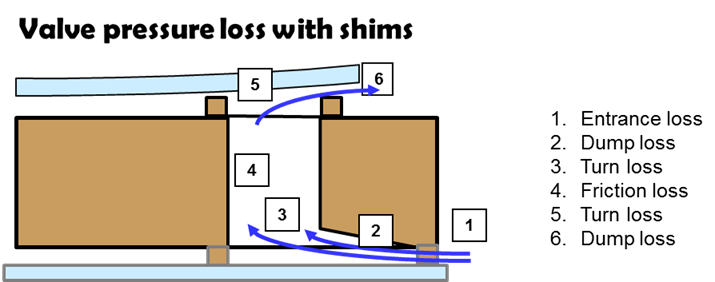

When shims are installed on the valve the valve port flow losses are different and much higher:

1: Entrance loss. With shims on the valve the flow enters the port through the narrow gap between the reverse stack face shim and valve deck. I believe the flow area of that gap may be much smaller than the valve port d.port minimum flow area we have been measuring for valves like the showa 50 oval. It would be interesting to know if it is smaller. At any rate the entrance flow losses for an installed valve with shim stacks on both sides of the port will be higher than the flow losses seen in the dyno tests where the port draws in flow from all directions.

2: Entrance dump loss: Once the flow has gone past the entrance it expands into the valve port area creating a flow loss.

3: Entrance turn loss: At point three the flow turns to the axial direction creating a flow loss.

4: Friction loss: Friction losses through the valve port are measured in the dyno all shims removed tests. This is the only flow loss that gets measured.

5: Exit turn loss: The flow turns from the axial direction toward the shim stack gap exit. Whether the gap is large or small the magnitude of this turning loss is about the same. For that reason I think it should be treated as a valve port loss, not a shim stack loss.

6: Exit dump loss: This loss is controlled by the shim stack stiffness.

Loss number 6 is controlled by the stiffness of the shim stack. All of the other losses are due to the valve port geometry. Of these 5 losses the “all shims removed” tests only measure the port skin friction loss. The tests do not measure the entrance and turning losses in the valve port. I believe these losses are much higher than the friction losses and the reason why ReStackor shows much higher port losses when compared to the dyno “all shims removed” data.

When trying to measure the effect of different valve port geometries on port flow losses I think you would get more realistic data if you put a single shim on both sides of the valve with a small clamp. With shims installed the flow is forced through the port entrance gap and through the port turning losses producing flow losses and a measured dyno force that is similar to the port flow losses occurring in an actual installed valve test. By running a single shim the stack is soft and exit flow restriction due to the stack stiffness would be small.

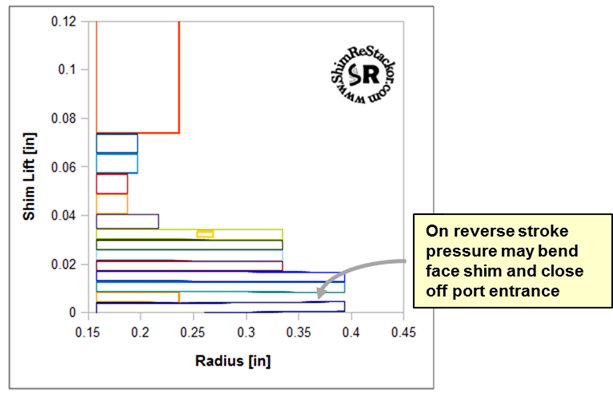

Entrance Flow Restriction:

Differences in entrance flow restrictions may be a part of the test-to-test variations we see in the dyno data. The pressure in the valve port is less than the upstream reservoir pressure due to the entrance loss, entrance dump and flow turning losses in the valve port. The reduced port pressure may cause the face shim on the reverse stack to bow downwards partially closing off the entrance flow area. If that happens the entrance flow losses will be higher.

Test-to-test differences in face shim thickness or cross over location on the reverse stack may cause one test to have a larger entrance restriction when compared to another. Also, when there is a large stack of thin face shims the shims may be hydraulically “stuck” together preventing the shims from deflecting downward in one test but not in another. To prevent test-to-test variations in entrance flow losses it may be useful to replace a tall stack of thin face shims with a single 0.2mm shim on the face to reduce reverse bowing of the face shim and the increased entrance flow restrictions when that occurs.

The inlet port restriction is going to be tuff to measure.

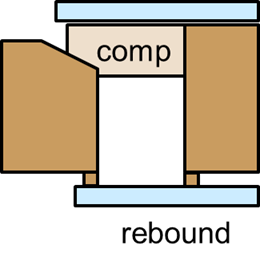

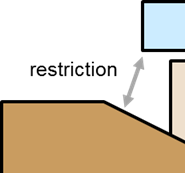

The above is an attempted cutaway of a shock valve with different compression and rebound shim diameters. The rebound port flow restriction may be on the flat part of the valve “deck” or the sloped section dropping away into the valve throat.

If the restriction is on the sloped section changing from a 44 to 43 or 42mm face shim may make a large difference in the minimum flow area. For the kyb46 wide valve you sent me it is possible to stick calipers down the port and attempt to measure the height on the sloped section. Not the best measurement, you may be able to figure out a better method.