Shim changes affect the entire force-velocity curve. Therefore, we always look at the changes made to the entire force-velocity curve when making all valving changes.

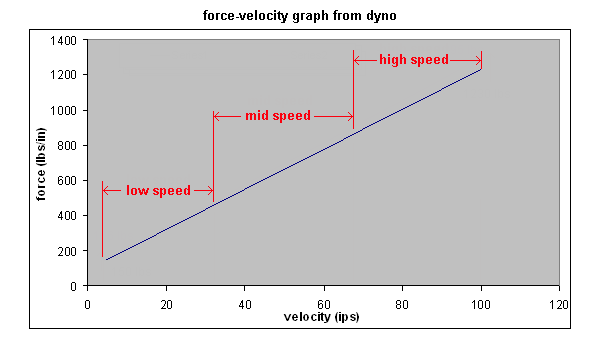

Chart 6 shows how the dyno's force-velocity curve might translate to the suspensions performance on the track (very approximate for this example).

Chart 6

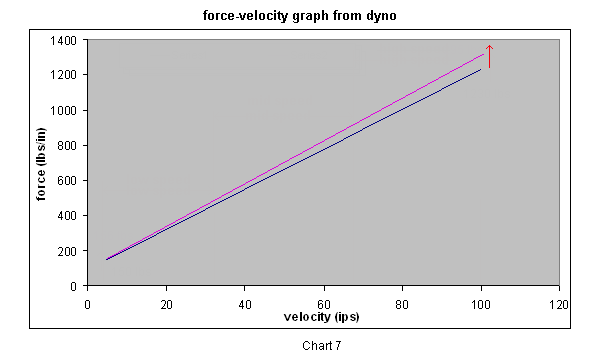

We can adjust the force-velocity curve in different ways. Chart 7 shows the original curve in blue. The pink line shows the altered curve where the low speed forces remain the same and the high speed forces are increased.

- The high speed end of the curve was increased by making the appropriate valving changes.

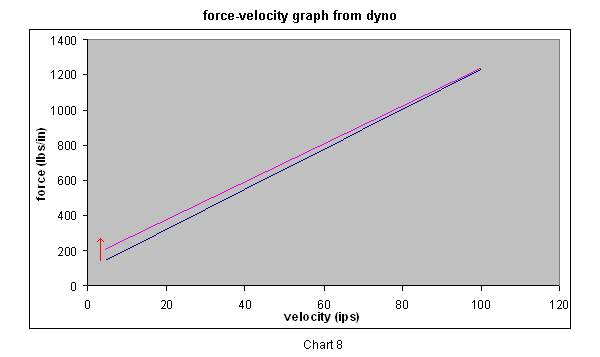

Chart 8 shows the low speed forces are increased and the high speed forces remain the same.

- The low speed end of the curve was increased by making the appropriate valving changes.

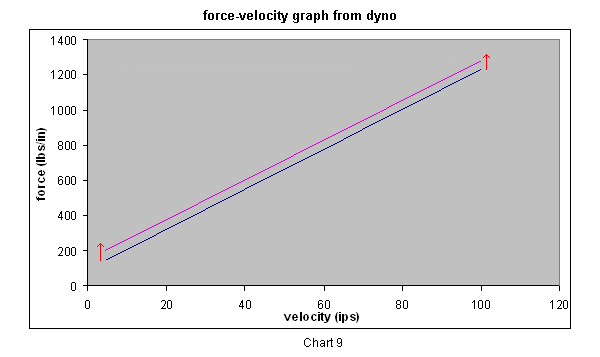

Chart 9 shows the low speed forces and high speed forces are increased.

- Both ends of the curve was increased by making the appropriate valving changes.

We always look at the entire force-velocity curve when making valving changes.

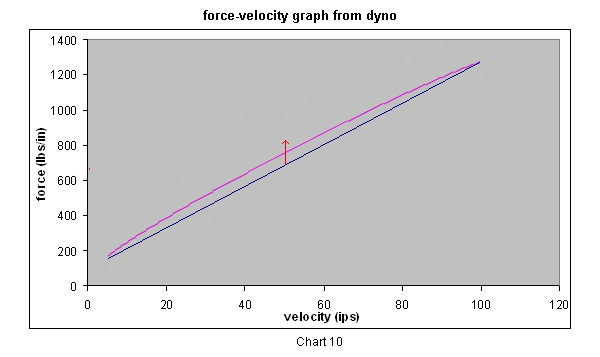

In the above examples, the shim changes altered either the beginning or ending point of the force-velocity curve. Generally speaking, you cannot directly influence just the middle of the curve with conventional shim configurations. However, if it were possible, it might look like the chart below.

Chart 10 shows an example of how the curve would look if the mid speed could be adjusted independent of low and high speed.

Valving possibilities are limitless. Dyno testing a damper will show exactly how shim changes affect the force-velocity curve, and rider feedback will tell you how the force-velocity curve translates to the dampers performance. That is the key to successful suspension tuning.